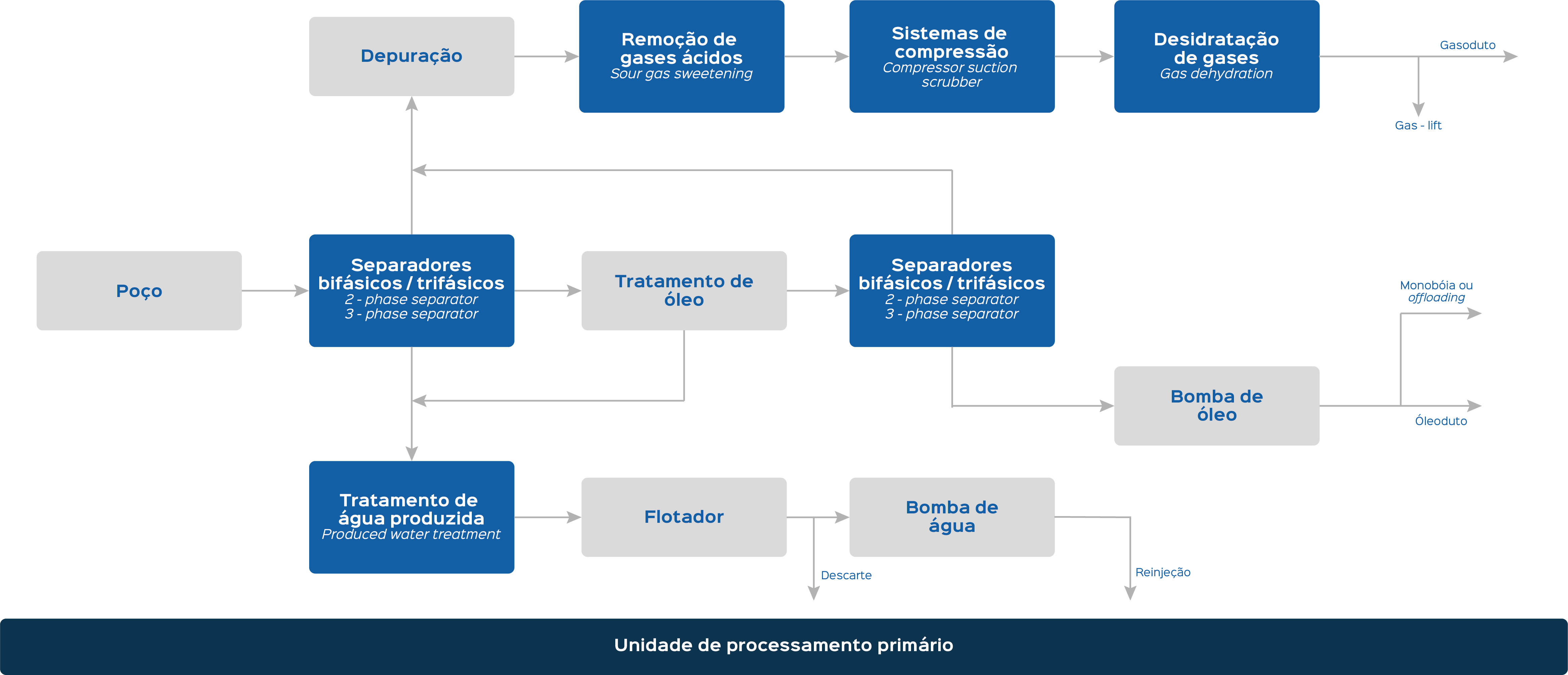

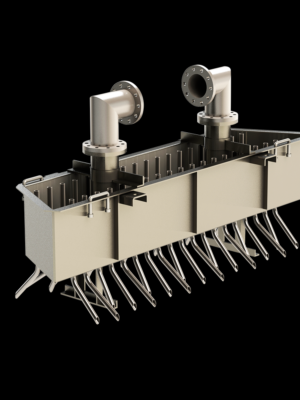

Clark Solutions offers the oil and gas industry a range of mass transfer and phase separation solutions, with a strong presence in the upstream and downstream sectors.

Our solutions are applied to the main production processes in this market with the aim of achieving the highest efficiency, increased capacity and operational safety and promoting the recovery of fluids with high added value.