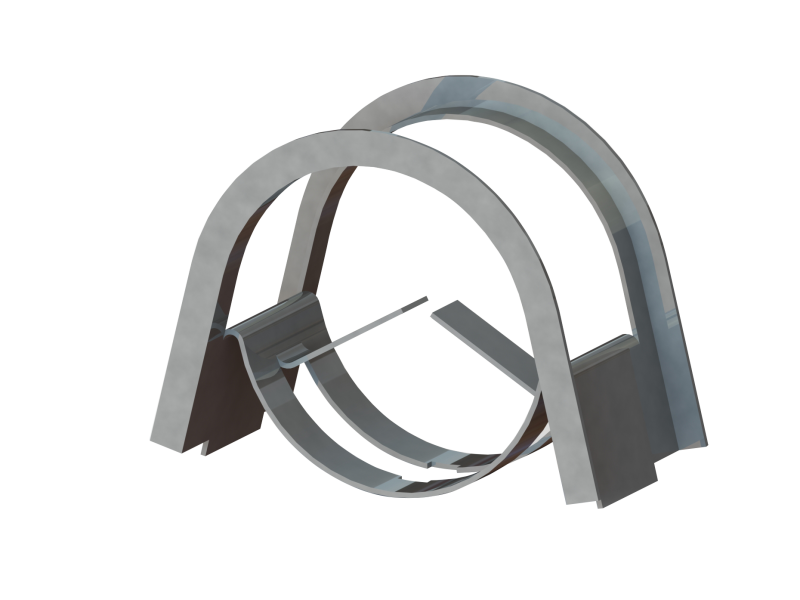

The random packing CMTP® seeks to associate high capacity with excellent mass transfer efficiency, promoting, also, a low pressure loss through its geometry. CMTP® is manufactured in an extensive range of metal alloys such as 410, 304, 316 and 317.

Its shape offers an excellent surface area and a constant renewal of the liquid film, maximizing the global mass transfer coefficient when comparing 1st and 2nd generation fillings (Raschig Rings and Pall Rings). In addition, there is a decrease in head loss when compared to conventional fillings.

The efficient mass transfer of this filling can be explained by factors such as:

– The uniformity of the distribution of liquid and steam in the section of the towers;

– Turbulence, which allows the renewal of the liquid film on its surface and, consequently, the increase in vapor-liquid interaction.

Both due to the high surface area / volume of the bed it promotes.