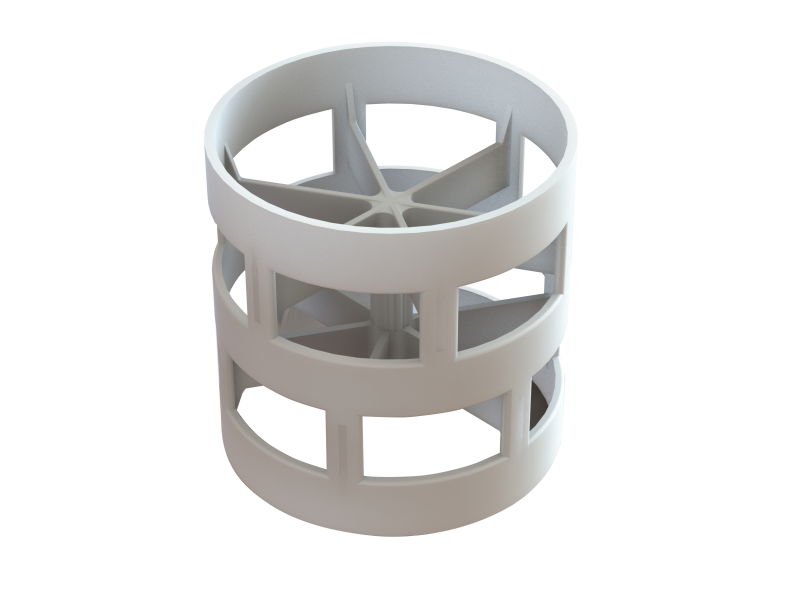

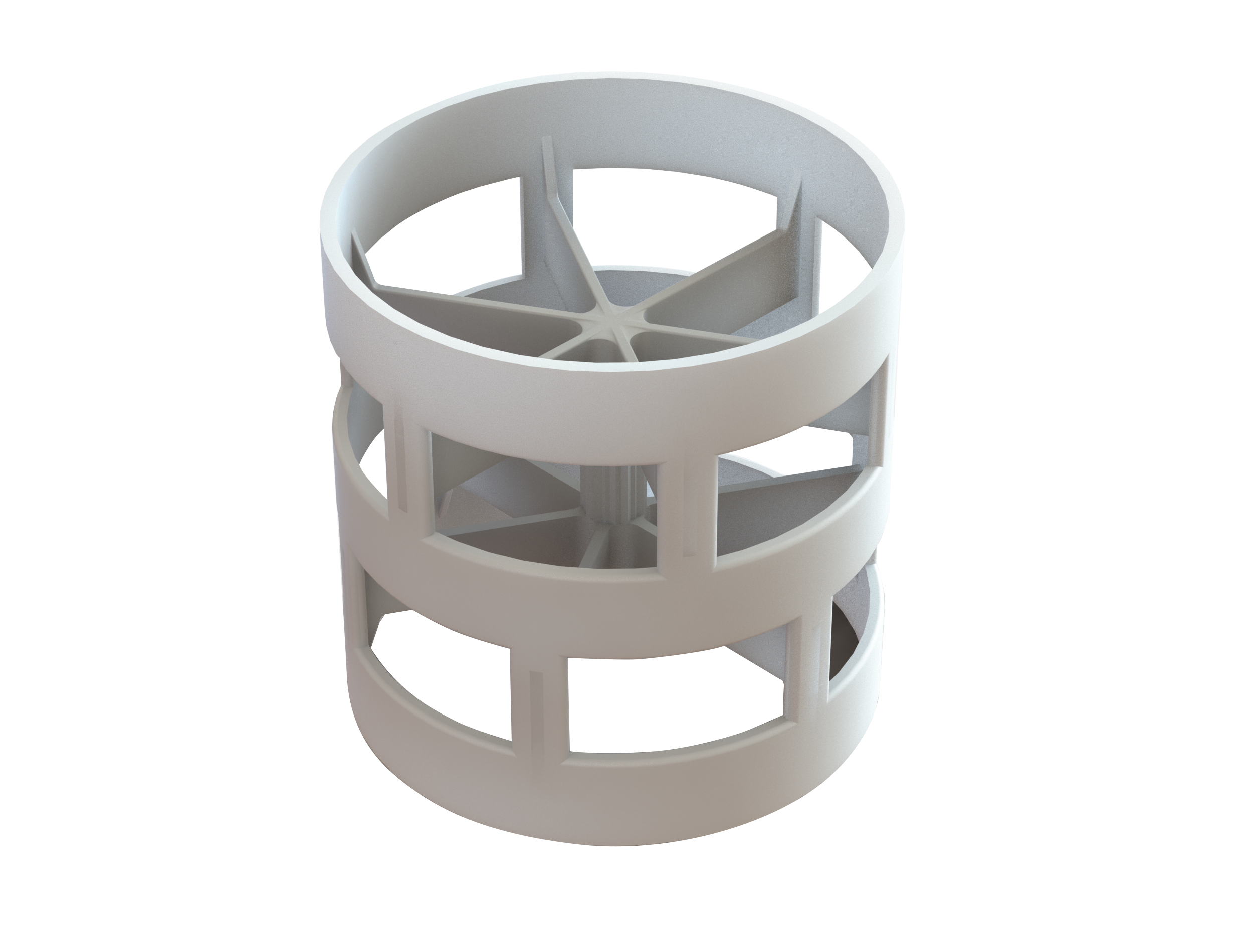

MaxiRing® random packing increase the efficiency of mass transfer in absorption and desorption processes. Therefore, the greater the contact area between the phases, the better the absorption efficiency.

The well-known Pall-ring is still widely used in all types of towers today, as it is suitable and performs well in almost any absorption or desorption process. Therefore, Clark Solutions presents the equivalent of this product, the so-called MaxiRing®.

In order to increase the contact area between the phases, random fillings were developed, through which the gas and liquid enter into counter current.

The MaxiRing® plastic can be manufactured in a variety of plastics, in order to meet temperature and chemical restrictions that will be exposed.

MaxiRing® can be manufactured in any metal or metallic alloy – the most common are stainless steels type AISI 304 and AISI 316, which have great resistance to corrosion and oxidation.