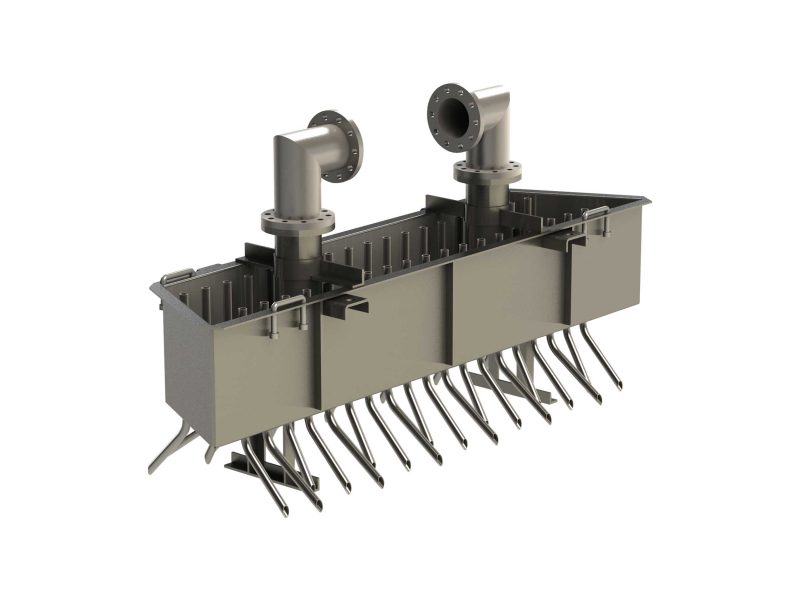

Clark Solutions MaxiFlow® CD liquid distributors are designed to optimize the transfer of gas-liquid mass to random ceramic fillings. They consist of a system of gutters with tubes (downcomers), which represent the independent irrigation points. The tubes enter the random filling, creating irrigation zones and reducing the formation of mist generation.

Designed for uniform distribution across the column section area, this configuration has a density of irrigation points designed according to the process.

How's it works?

Due to its high irrigation rate and density of irrigation points, MaxiFlow® CD generates uniformity in the distribution of the liquid, which avoids gas bypass regions and favors the mass transfer rate, in addition to providing less operating expenses.

Product Applications

The Clark Solutions MaxiFlow® CD liquid distributor was developed to optimize the transfer of gas-liquid mass. This consists of a system of gutters with tubes, which represent the independent irrigation points.

- Operation with corrosive or fouling fluids.

- Drying towers in the sulfuric acid and chlorine and soda industry;

- Absorption towers in the sulfuric acid and chlorine and soda industry.