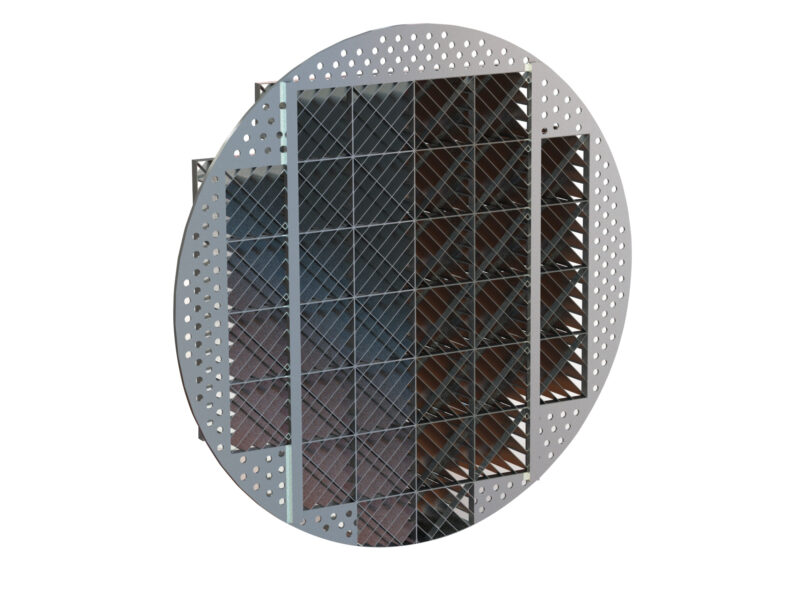

PlatePack® liquid-liquid coalescers consist of parallel plates uniformly arranged to increase the efficiency of liquid-liquid separation. They can be built with polymeric or metallic materials, depending on the application and have the objective of reducing the residence time necessary for the separation of the phases, since it favors the agglomeration of small particles inside the plates, which coalesce and return to the system.

PlatePack® is an excellent coalescing solution for emulsified particles with a diameter ≥ 40 µm, which provides excellent performance in systems prone to fouling.

How's it works?

Liquid-liquid coalescers are designed to laminarize the flow and improve the separation of phases by gravity of two immiscible liquids, causing an increase in the size of the drops of the dispersed phase, facilitating the decantation rate.

The droplets contact the surface of the slides, breaking the interfacial tension between the liquids to be separated, allowing multiple drops to come together to form larger drops or a continuous liquid film.

Product Applications

PlatePack® coalescers are designed to increase the separation efficiency and reduce the size of the coalescing vessel in processes with risk of fouling.

- Water treatment process with oily contaminants;

- System with suspended solids.

- Primary separators in the oil and gas industry;

- Hydrotreatment and hydrodesulfurization in refineries.