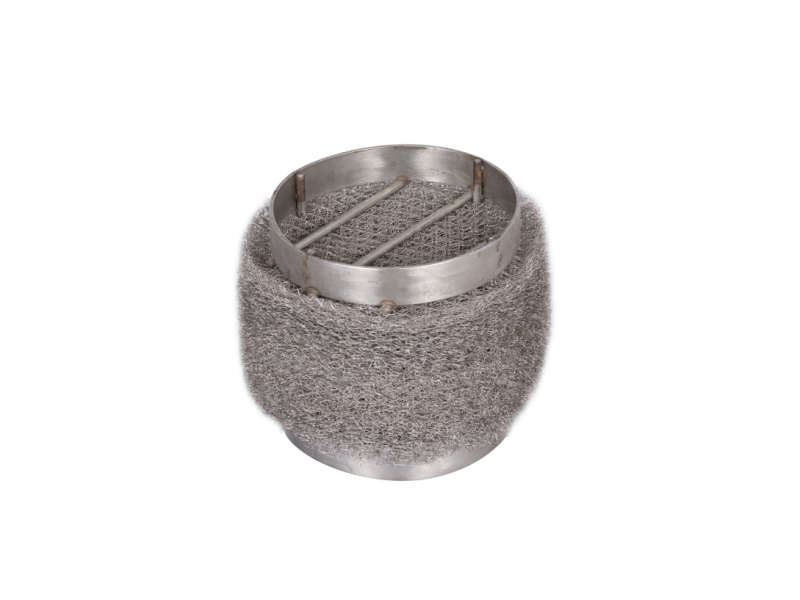

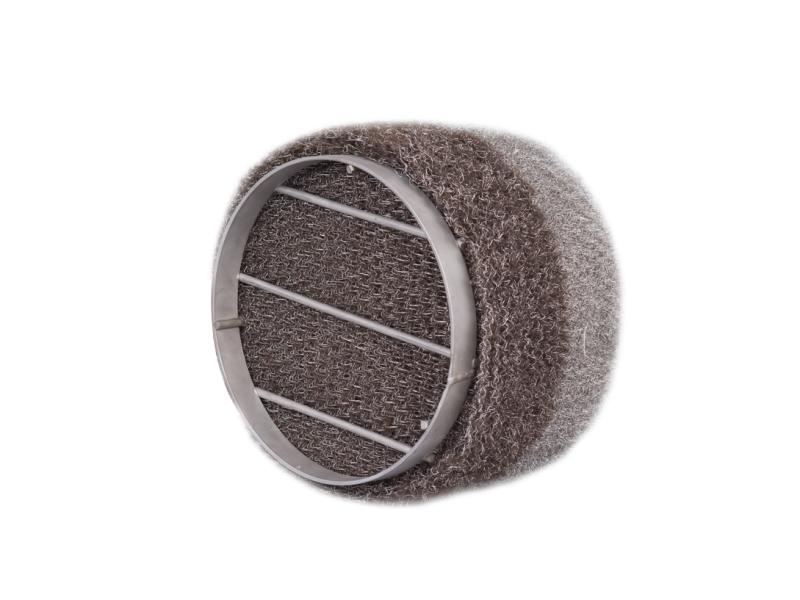

CS-Mesh® liquid-liquid coalescers can be manufactured in polymeric or metallic alloys in mesh structure, combined with thermoplastic polymers or glass fibers, in order to obtain high performance in several industry operations involving liquid-liquid phase separation .

The most varied models have different wire diameters and void fraction, in addition to the material being carefully chosen to have affinity with the dispersed phase, facilitating its adherence to the surface of the wires and, as other drops reach the surface, they coalesce and are detached from the mesh when big enough.

CS-Mesh® has versatility in interstitial diameter, porosity and construction material, in order to allow great affinity with the dispersed phase and the ideal adhesion to the mesh, the increase in the size of the droplets can be obtained quickly and the coalescence is highly efficient even for very stable emulsions.

The fixation can be configured with single or double support, or without welding, and can be designed according to its spacing and position within different equipment.

Instead of segregating substances through cross-flow drainage in relation to the main flow, the mesh induces the dispersed and small droplets to agglomerate and increase in volume, thus being transported by the gravitational force and moving away from the continuous phase in the subsequent stages of the separating vessel . It can be designed according to its spacing and position within different equipment.