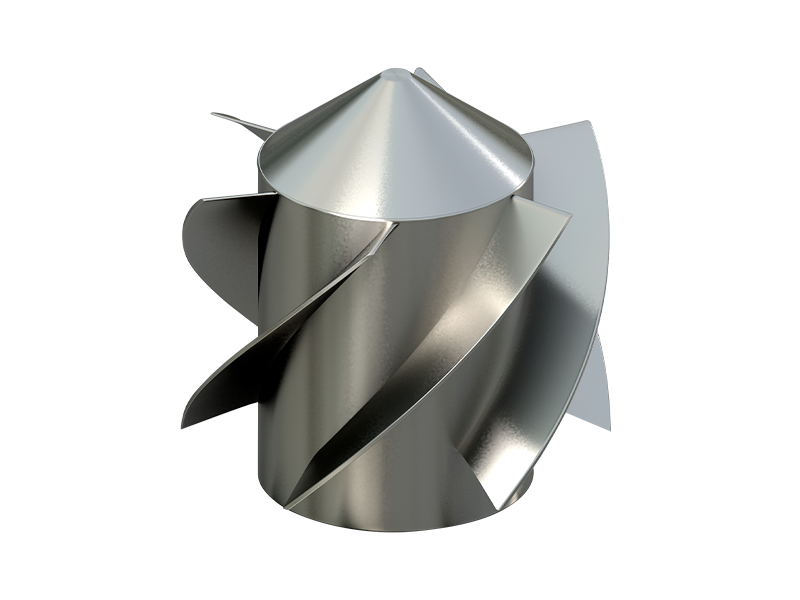

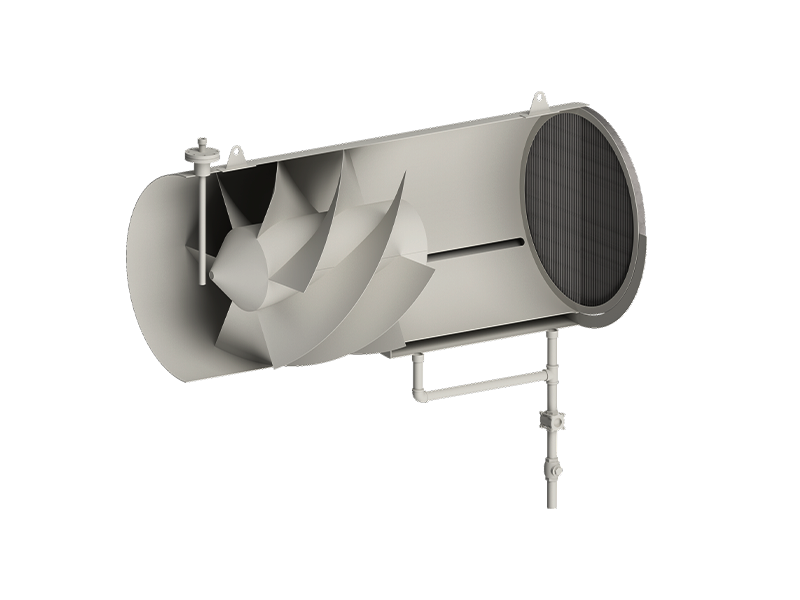

MaxiSpin® mist eliminators is an axial cyclone that retains, by centrifugal force, all liquid particles entrained by the gas flow.

Designed to maintain efficiency in transient processes, with variations in flow, temperature and pressure, this centrifugal drag separator captures 99% of the particles at around 10-20µm with low pressure loss throughout the process.

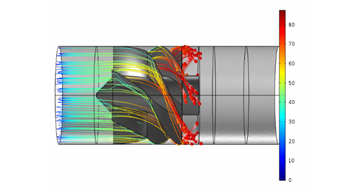

To promote the extraction of particles, MaxiSpinforces the rotation of the gas stream and the entrained drops cannot follow the movement of the gas and coalesce on the pipe walls.

It is also known that the greater the difference in density between the phases, the greater the centrifugal force and, consequently, there is an increase in the speed of the particle towards the pipe wall, forcing these to coalesce more easily and to be drained. After this drainage, it is possible to recover these particles and reduce losses.

The MaxiSpin ™ drag separator can be used in any process in the chemical industry, being commonly used in the sugar and alcohol industry to prevent the broth from being dragged in the steam from evaporators and cookers.