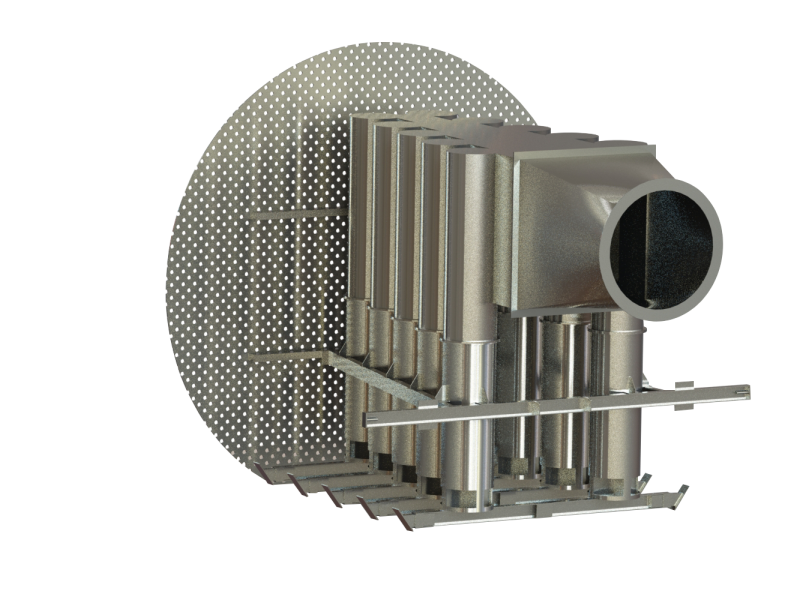

As the inlet load increases, CS FoamBreaker® inlet devices become the best solution for increasing vessel capacity. For the conditions of greatest moments at the entrance, Clark Solutions has developed a system of cyclones of entry, which pre-separate most of the small bubbles and drops. High-speed liquid flows tend to create foam, which hinders the separation between the phases, so the CS FoamBreaker® is designed to break foam bubbles, while separating the gas and liquid phases.

Like all inlet devices, CS FoamBreaker® is sized for each vessel and process, allowing for high performance, high level of separation (pre-separates more than 96% of the input mixture) and smooth flow within the vessel.

How's it works?

O CS-FoamBreaker® possui uma entrada que divide a vazão em porções iguais para os ciclones em paralelo. Essas porções entram tangencialmente no ciclone, gerando fluxo rotacional que quebra a espuma e separa de forma eficiente as fases gás e líquida.

In the center there is the formation of a column of gas that flows through the top of the cyclone, while the liquid phase exits through lateral openings in the tube wall at the bottom, leaving for the liquid layer in which it is submerged.

Product Applications

Like all input devices, CS FoamBreaker® is sized for each vessel and process, allowing for high performance, high level of separation (pre-separates more than 96% of the input mixture) and smooth flow within the vessel.

- It is necessary to break the incoming foam;

- High input momentum systems.

- Safety KO Drum;

- Primary Tabs.