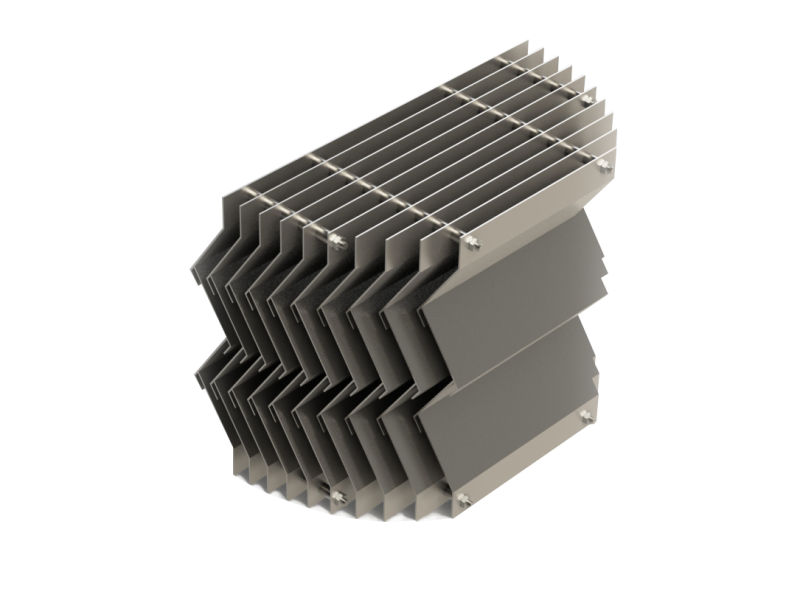

MaxiChevron® mist eliminators are devices manufactured using a set of parallel vertical blades with an undulating profile.

The geometry of this system, the number of movements of the gas inside the system, the angle and distance between the blades and a series of factors are carefully designed to achieve maximum separation efficiency in each process situation (flow, pressure, temperature , entrained liquid charge, etc.).

How's it works?

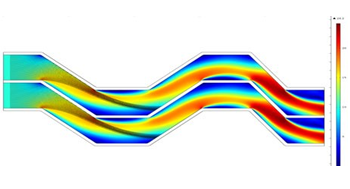

In the image it is possible to observe the alternation in the direction of the blades. The colored background represents the speed variation along the MaxiChevron and the black lines simulate particles dragged by the flow. The variation in the direction of flow, close to the wall, allows the particles to gain high speeds, collide and clump together until they are drained.

Product Applications

The MaxiChevron® drag separator can be used in several types of chemical industry, being commonly used in the sugar and alcohol industry.

In the sugar and alcohol industry, they are designed to be installed internally in evaporators and cookers or externally, in shelter pots, in the vegetable steam line.

- Trailing liquids;

- Capture of particles of approximately 10 + µm;

- Need for low head loss.

- Cookers in the sugar and alcohol industry;

- Primary separators in the oil and gas industry;

- Safety Gas in the oil and gas industry;

- Compression scrubber in the oil and gas industry;

- Amine tower and TEG tower in the oil and gas industry.